Oil-Free Scroll Air Compressor Of CMW Series

Precise host High-precision, rigid and durable square host ensures that the pressure can reach 1.2MPa Permanent magnet inverter VSD soft start without current impact. Frequency conversion automatically adjusts the motor speed, energy saving and long service life; Compress Air with Low Temperature Low Discharge The temperature of the compressed air is close to the ambient temperature, and after being cooled by an independent fan, the low pressure dew point is ensured. Intelligent structure and advanced sound insulation shell reduce noise… FOB price: 0.5 USD- 9,999 / pcs Minimum order quantity: 100 pcs / pcs Supply Ability: 10000 pcs per month Payment terms: L/C, D/A, D/P, T/T Here is the introduction of oil-free scroll air CMW series compressor The machine hopes to help you understand it better

Oil-Free Scroll Air Compressor

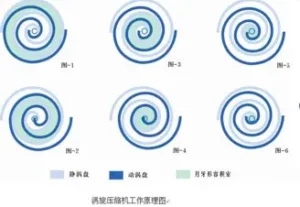

An oil-free scroll air compressor is a type of air compressor that operates without the need for oil lubrication. Instead of using oil to lubricate the compressor’s moving parts, an oil-free scroll compressor uses a pair of interlocking spiral scrolls that compress the air without touching it. This design eliminates the need for oil, which can contaminate the compressed air and make it unfit for certain applications.

Oil-free scroll compressors are ideal for applications that require clean, dry, oil-free air, such as food processing, electronics manufacturing, pharmaceutical production, and laboratory research. They are also energy-efficient compared to other types of compressors because of their simple design and the fact that they use fewer moving parts.

One disadvantage of oil-free scroll compressors is that they generally have a lower maximum pressure than traditional oil-lubricated compressors. Additionally, because of the complexity of their design, they can be more expensive to purchase and maintain than other types of compressors.

Precision Air End

High-precision, rigid, and durable square host ensures pressure up to 1.2MPa

Permanent magnet inverter

VSD soft start without current impact. Frequency conversion automatically adjusts the motor speed, energy saving, and long service life;

cryogenic compressed air

The temperature of the exhaust compressed air is low, and after being cooled by an independent fan, it is close to the ambient temperature, ensuring a low-pressure dew point. The intelligent structure and advanced sound insulation shell reduce the noise to 49dB(A)

Technical Parameter of Oil-free Scroll Air Compressor of CMW Series

|

Model |

Motor power |

Working pressure |

FAD |

Noise |

Compressed Air Outlet Diameter |

Weight |

Dimension |

||

|

L×W×H |

|||||||||

|

kW |

HP |

MPa |

L/min |

cfm |

dB(A) |

inch |

kg |

mm |

|

|

CMW2.2-0.8 |

2.2 |

3 |

0.2-0.8 |

255 |

9 |

49±3 |

1/2″ |

132 |

670×630×945 |

|

CMW3.7-0.8 |

3.7 |

5 |

0.2-0.8 |

415 |

15 |

52±3 |

1/2″ |

150 |

720×680×1050 |

|

CMW4.4-0.8 |

2.2×2 |

6 |

0.2-0.8 |

510 |

18 |

52±3 |

1/2″ |

150 |

800×650×1020 |

|

CMW7.4-0.8 |

3.7×2 |

10 |

0.2-0.8 |

830 |

29 |

55±3 |

1″ |

185 |

880×720×1120 |

|

CMW11-0.8 |

3.7×3 |

15 |

0.2-0.8 |

1245 |

44 |

58±3 |

1″ |

300 |

1450×900×1150 |

|

CMW15-0.8 |

3.7×4 |

20 |

0.2-0.8 |

1660 |

59 |

61±3 |

1″ |

350 |

1450×900×1150 |

|

CMW2.2-1.0 |

2.2 |

3 |

0.2-1.0 |

215 |

7.6 |

49±3 |

1/2″ |

132 |

670×630×945 |

|

CMW4.5-1.2 |

4.5 |

6 |

0.2-1.0 |

410 |

14.5 |

52±3 |

1/2″ |

150 |

720×680×1050 |

|

CMW4.4-1.0 |

2.2×2 |

6 |

0.2-1.0 |

430 |

15 |

52±3 |

1/2″ |

150 |

800×650×1020 |

|

CMW9-1.0 |

4.5×2 |

12 |

0.2-1.0 |

820 |

29 |

58±3 |

1″ |

185 |

880×720×1120 |

|

CMW13.5-1.0 |

4.5×3 |

18 |

0.2-1.0 |

1230 |

43.3 |

61±3 |

1″ |

300 |

1450×900×1150 |

|

CMW18-1.0 |

4.5×4 |

25 |

0.2-1.0 |

1640 |

58 |

61±3 |

1″ |

350 |

1450×900×1150 |

|

CMW3.0-1.2 |

3 |

5 |

0.2-1.2 |

210 |

7.4 |

49±3 |

1/2″ |

135 |

670×630×945 |

|

CMW4.5-1.2 |

4.5 |

6 |

0.2-1.2 |

360 |

12.7 |

52±3 |

1/2″ |

150 |

720×680×1050 |

|

CMW6.0-1.2 |

3×2 |

8 |

0.2-1.2 |

420 |

14.8 |

52±3 |

1/2″ |

150 |

800×650×1020 |

|

CMW9-1.2 |

4.5×2 |

12 |

0.2-1.2 |

720 |

25.4 |

58±3 |

1″ |

185 |

880×720×1120 |

|

CMW13.5-1.2 |

4.5×3 |

18 |

0.2-1.2 |

1080 |

38 |

61±3 |

1″ |

300 |

1450×900×1150 |

|

CMW18-1.2 |

4.5×4 |

25 |

0.2-1.2 |

1440 |

50.8 |

61±3 |

1″ |

350 |

1450×900×1150 |

Applications for Industrial Oil-Free Air Compressors

Oil-free compressed air is a powerful production method for companies that need to produce products with air purity and product safety in mind. Oil-free compressors are always ISO Class Zero certified and provide a 100% oil-free air supply for sensitive applications. Some industry application examples include:

- Automotive: Oil-free compressed air creates high-quality automotive paint finishes in a smooth process.

- Food and beverage: The oil-free approach creates healthier foods while also eliminating any possibility of oil contamination.

- Chemical: The chemical industry benefits from oil-free air compressors as these machines increase purity, reduce waste and increase safety.

- Electronics: Oil-free methods are critical for electronics as they provide uninterrupted control systems in ultra-clean conditions for the production of delicate devices such as motherboards.

- Pharmaceuticals: Oil-free air compressors reduce the risk of oil contamination in pharmaceutical products and help improve production efficiency.

When you want to produce products in environments where oil contamination can cause equipment damage or lead to costly damage and recalls, oil-free air compressors are the perfect solution to achieve the highest standards of air purity.

Packaging Process